Permeability

Many GCTS Rock Systems can be upgraded to perform permeability tests through various methods, including conventional permeability, pulse-decay permeability, and relative permeability.

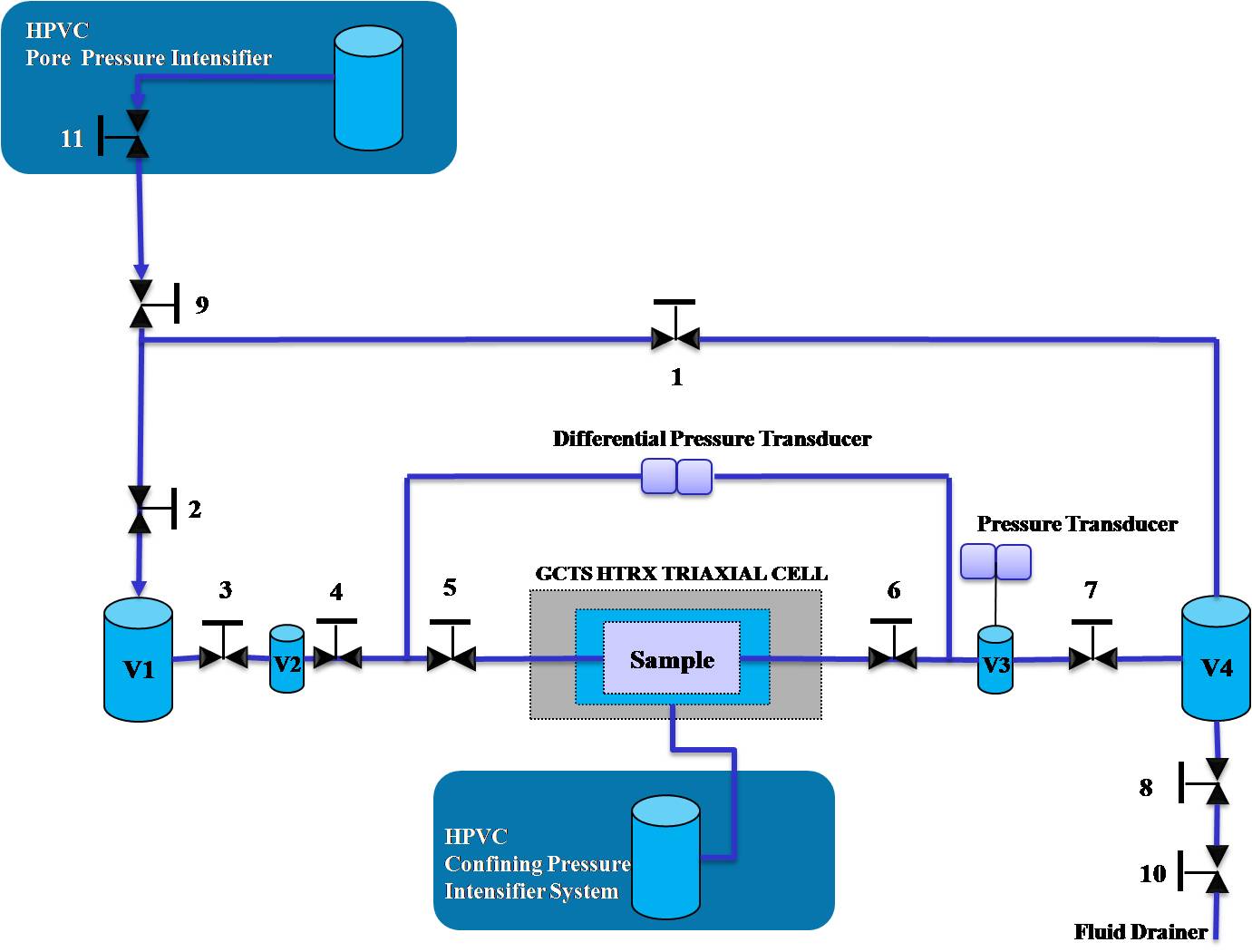

All GCTS Rock Triaxial Systems that are equipped with pore pressure control can perform conventional permeability testing as a standard feature. An additional setup can be provided with a differential pressure transducer to perform conventional permeability tests with elevated back pressure.

The GCTS Fast Pulse-Decay Permeability Apparatus (HPPD-20) is designed for measurement of permeability in micro-porous material, such as gas shale and other reservoir rocks, in order to determine the capacity and flow characteristics of the rock matrix. The HPPD-20 is capable of measuring rock permeability less than 1 μD (microdarcy). The system components are secured in an insulated metal cabinet with front-panel-mounted valves and controls. It features precise temperature control inside the cabinet to eliminate errors caused by temperature-induced volume expansion and contraction of the fluid and gas inside the reservoirs.

GCTS also offers a Relative Permeability Separator (HPVC-RP-Separator) to allow a single, mixed pore fluid to exit a rock specimen and be separated into its two component fluids. The separator includes three clear sight tubes to manually determine the relative permeability of the two fluids once they have exited the specimen.

HPPD Series

HIGHLIGHTS

- 20, 30, or 70 MPa absolute pressure capacity

- 800 kPa differential pressure capacity

- Two (2) 100 cc volume stainless steel reservoirs

- Two (2) 5 cc volume stainless steel reservoirs

- Nine (9) zero-volume-change ball valves

- Two (2) pressure transducers for upstream and differential pressures

- Integrated temperature control system

- Metal alloy models available for use with corrosive fluids

- Models available with higher-volume reservoirs

- Two (2) 2,000 cc volume stainless steel reservoirs

- Two (2) 500 cc volume stainless steel reservoirs