Electromechanical Load Frame

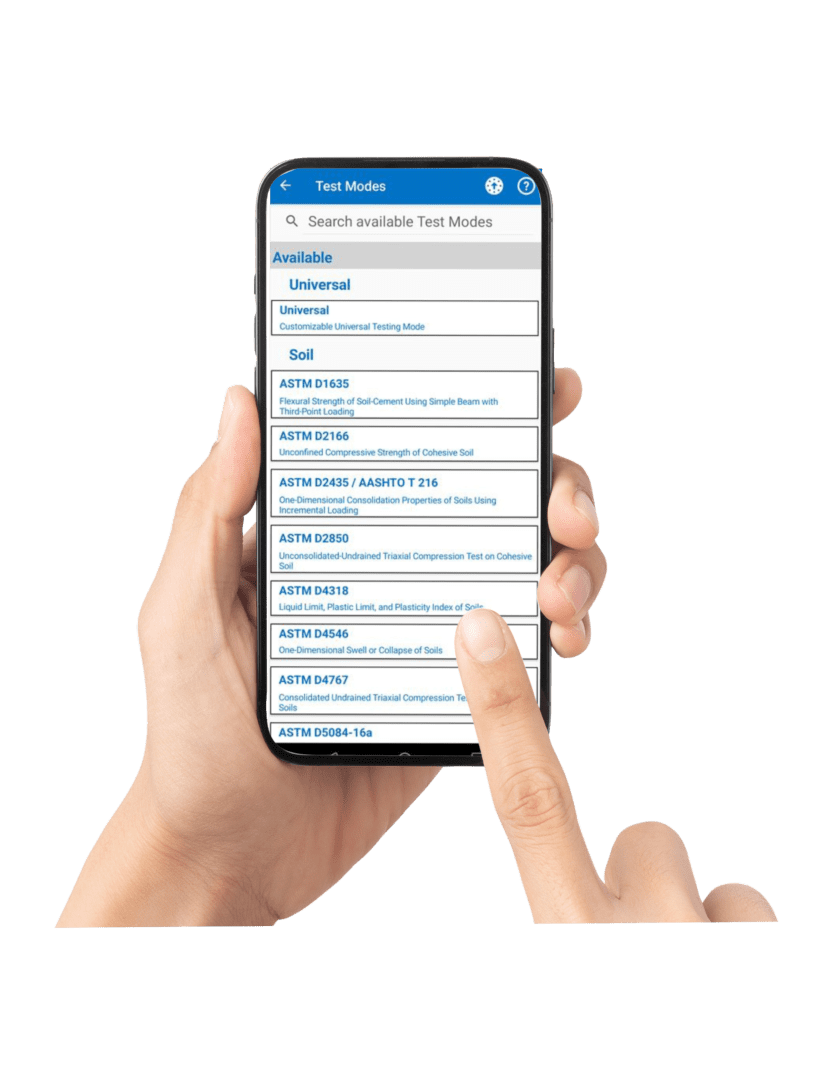

Electromechanical load frame with two-column vertical standing assembly and threaded columns for crosshead adjustment and closed-loop control of axial load/stress or axial displacement/strain. Servo control with closed-loop feedback from any of the eight (8) input channels or any real-time calculated function. The eFRM load frame can accommodate a large range of test fixtures. GCTS offers a large range of test apps for specific standards or custom test methods. GCTS offers several eFRM models, all of which have a 100 mm stroke with four (4) ADC channels with excitation (5 VDC or 10 VDC), simultaneous sampling, internal filtering, and selectable input range (from ±2.4 mV to ±20 V) and four (4) ADC channels with ±10 VDC fixed range.

- eFRM-20

- eFRM-20D

- eFRM-50

- eFRM-90

- eFRM-90S

- Asphalt Relevant Standards

- Concrete Relevant Standards

- Environmental Chamber (Coming Soon)

eFRM-20

HIGHLIGHTS

- 100-mm (4 inch) stroke

- 20 kN (5,000 lbf) Axial load capacity, up to 90 kN capacity available

- SR-LC-SSM-20k Load cell ±20 kN range. 0.05% precision

- Maximum vertical daylight opening: 595 mm

- Horizontal daylight opening: 279 mm

- Axial actuator speed range: 0.003 mm/min to 100 mm/min – (max 25 mm/min at full 20 kN load)

- Cyclic loading frequency up to 0.1 Hz with 10 mm peak-to-peak amplitude

- Four (4) ADC channels with excitation (5 VDC or 10 VDC), simultaneous sampling, internal filtering, and selectable input range (from ±2.4 mV to ±20 V)

- Four (4) ADC channels with ±10 VDC fixed range

- TCP/IP Communication

- Power Requirement: 90-260 VAC, 50-60 Hz

eFRM-20D

HIGHLIGHTS

- 100-mm (4 inch) stroke

- 20 kN (5,000 lbf) Axial load capacity

- SR-LC-SSM-20k Load cell ±20 kN range. 0.05% precision

- Maximum vertical daylight opening: 595 mm

- Horizontal daylight opening: 279 mm

- Axial actuator speed range: 0.003 mm/min to 600 mm/min

- Cyclic loading frequency up to 2 Hz

Includes an integrated data acquisition unit with the following specifications:

- Four (4) ADC channels with excitation, simultaneous sampling, internal filtering, and

selectable input range. - Four (4) ADC channels with ±10 VDC fixed range

- TCP/IP Communication

Power Requirement: 90-260 VAC, 50-60 Hz, 8 A @ 1 KVA

eFRM-50

HIGHLIGHTS

- 100-mm (4 inch) stroke

- 50 kN Axial load capacity

- SR-LC-LP50 ±50 kN (11 kip) Low Profile Precision Universal Load Cell with Base. 0.05% precision.

Includes an integrated data acquisition unit with the following specifications:

- Four (4) ADC channels with excitation, simultaneous sampling, internal filtering, and

selectable input range. - Four (4) ADC channels with ±10 VDC fixed range

- TCP/IP Communication

Power Requirement: 90-260 VAC, 50-60 Hz, 8 A @ 1 KVA

eFRM-90

HIGHLIGHTS

- Precise Closed-Loop Control: The eFRM-90 allows for precise closed-loop control of net deformation or crack mouth opening, enabling accurate measurement and control of critical parameters during testing.

- Flexible Control Options: You can easily change the feedback control mid-test from Load, displacement, net deflection, or CMOD, making it adaptable to various testing scenarios.

- Cost-Effective Solution: This system offers an economical option for commercial labs, eliminating the need for expensive and complex test setups.

- User-Friendly: Designed with ease of use in mind, the eFRM-90 is ideal for both seasoned professionals and newcomers to concrete testing.

- Comprehensive Testing Capabilities: It can perform a range of standard tests such as EN 14651, ASTM C1609/C1609M-19, and customized beam tests. Additionally, it offers a library of Apps to perform different ASTM and EN standards, including unconfined compression and indirect tension tests.

- Directional Control: The system excels in controlling displacement along the direction of the least principal stress, making it suitable for brittle materials like concrete and rock.

- Flexural and Direct Tension Testing: It is particularly well-suited for flexural and Direct Tension Tests (DTT) by accurately measuring and controlling crack opening, ensuring stable post-peak control.

- Customizable Procedures: Standard testing procedures can be easily customized, allowing for a combination of feedback control variables that can switch mid-test based on predefined threshold values or peak reversals.

- Additional Testing Capabilities: The eFRM-90 is compatible with fixtures and application software for measuring the modulus of elasticity, Poisson’s ratio, indirect tension, and more.

- Complex Loading Paths: This system can handle complex load or deformation paths, making it valuable for studying the intricate behavior of fiber-reinforced concrete under cyclic tension-tension and tension-compression loading.

- Maximum vertical daylight opening: 1209 mm

- Horizontal daylight opening: 405 mm

- TCP/IP Communication

- Power Requirement: 90-260 VAC, 50-60 Hz

eFRM-90S

HIGHLIGHTS

The GCTS eFRM-90S is a precision-controlled electro-mechanical loading frame designed for post-crack performance testing of Fiber Reinforced Concrete (FRC). This system combines precision with versatility, offering unmatched closed-loop control of net deformation, crack mouth opening (CMOD) or any other real time calculated parameter. It’s compact design, cost-effective and user-friendly design makes it a smart option for commercial labs. GCTS offers a broad spectrum of standard and customized tests, as well as fixtures and predefined Apps. Whether you intend to perform Q/C commercial work or research testing, the eFRM-90S promises accuracy, adaptability, and affordability, truly setting a gold standard in the industry.

- High Stiffness: 225 kN/mm allows for post failure analysis of the specimen

- Precise Closed-Loop Control: The eFRM-90S allows for precise closed-loop control of net deformation or crack mouth opening, enabling accurate measurement and control of critical parameters

during testing. - Flexible Control Options: You can easily change the feedback control mid-test from Load, displacement, net deflection, or CMOD, making it adaptable to various testing scenarios.

- Cost-Effective Solution: This system offers an economical option for commercial labs, eliminating the need for expensive and complex test setups.

- User-Friendly: Designed with ease of use in mind, the eFRM-90S is ideal for both seasoned professionals and newcomers to concrete testing.

- Comprehensive Testing Capabilities: It can perform a range of standard tests such as EN 14651, ASTM C1609/C1609M-19, and customized beam tests. Additionally, it offers a library of apps to perform different ASTM and EN standards, including unconfined compression and indirect tension tests.

- Directional Control: The system excels in controlling displacement along the direction of the least principal stress, making it suitable for brittle materials like concrete and rock.

- Flexural and Direct Tension Testing: It is particularly well-suited for flexural and Direct Tension Tests (DTT) by accurately measuring and controlling crack opening, ensuring stable post-peak control.

- Customizable Procedures: Standard testing procedures can be easily customized, allowing for a combination of feedback control variables that can switch mid-test based on predefined threshold values or peak reversals.

- Additional Testing Capabilities: The eFRM-90S is compatible with fixtures and application software for measuring the modulus of elasticity, Poisson’s ratio, indirect tension, and more.

- Complex Loading Paths: This system can handle complex load or deformation paths, making it valuable for studying the intricate behavior of fiber-reinforced concrete under cyclic tension-tension and tension-compression loading.

Asphalt Relevant Standards

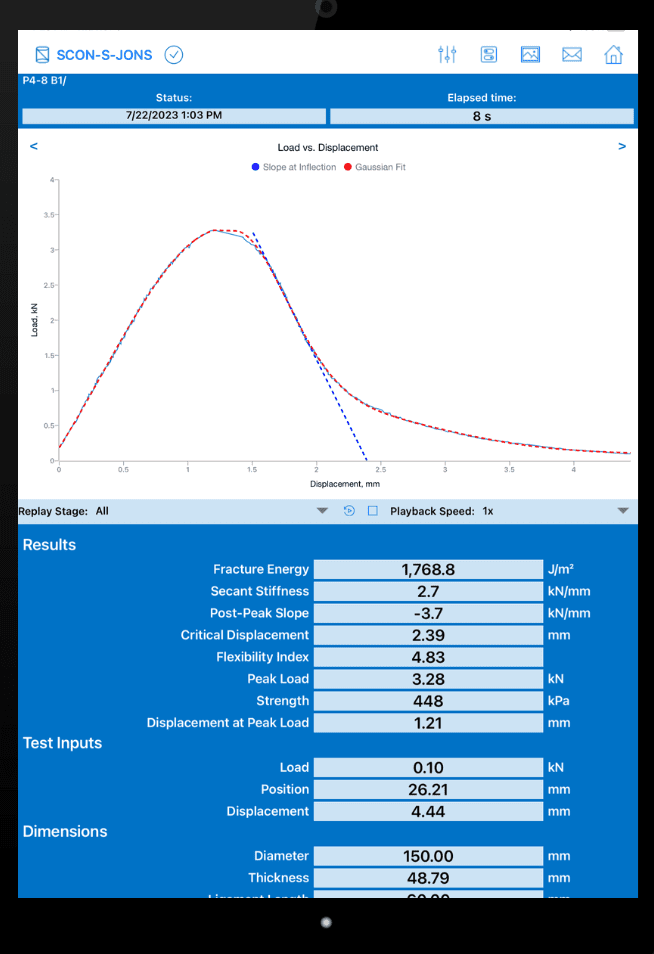

SCB (Semi-Circular Bending)

- EN 12697-44:2019 Bituminous mixtures. Test methods – Crack propagation by semi-circular bending test

- AASHTO TP 105-13 Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry

- ASTM D8044-16 Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures

- AASHTO TP 124-18 Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using the Flexibility Index Test (FIT)

IDT (Indirect Tension – Full Circular Sample)

- ASTM D8225-19 Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature

- ASTM D6931 Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures

- AASHTO T322 Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device

- BS EN 12697-23 Bituminous mixtures. Test methods – Determination of the indirect tensile strength of bituminous specimens

- AASHTO T283 Resistance of CompactedAsphalt Mixtures toMoisture-Induced Damage

Ideal-RT Test Fixture

- ASTM D8360 Standard Test Method for Determination of Rutting Tolerance Index of Asphalt Mixture Using the Ideal Rutting Test

Texas Overlay

- Tex-248-F Critical fracture energy and crack progression rate are performance indices that characterize the bituminous mixtures resistance to cracking. This test method determines the susceptibility of bituminous mixtures to fatigue or reflective cracking

Asphalt Tack Coat/Interlayer Shear Strength Fixture

- AASHTO TP 114-18 Standard Method of Test for Determining the Interlayer Shear Strength (ISS) of Asphalt Pavement Layers

Asphalt Disk-Shaped Compact Tension (DCT) Fixture

- ASTM D7313 Standard Test Method for Determining Fracture Energy of Asphalt Mixtures Using the Disk-Shaped Compact Tension Geometry

- AASHTO TP 105 Standard Method of Test for Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB)

Marshall Fixture

- ASTM D6926 Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus

- ASTM D6927 Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures

- AASHTO T245 Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus

- BS 598-107 Sampling and examination of bituminous mixtures for roads and other paved areas – Method of test for the determination of the composition of design surface course rolled asphalt

California Bearing Ratio (CBR)

- STM D1883 Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils

specimens, soaking them, and then measuring their resistance to penetration1. - AASHTO T193 Standard Method of Test for The California Bearing Ratio

- BS 1377-9 Methods for test for soils for civil engineering purposes. In-situ tests

Concrete Relevant Standards

Flexural Beam Fixture

- STM C78/C78M Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

- ASTM C293/C293M Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)

- ASTM C1399/C1399M Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete

- ASTM C1609/C1609M Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)

- BS EN 12390-5 Testing hardened concrete – Flexural strength of test specimens

Unconfined Compression Platens

- ASTM C39 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

- ASTM C469/C469M Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression

- ASTM D7012 Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures

- BS 1881-121 Testing concrete – Method for determination of static modulus of elasticity in compression

Direct Tension of Concrete beams Fixture

- No testing standards are currently available. Includes customized testing App with selection of load, stress, displacement or CMOD (average o individual) control.

- This fixture includes self-aligning swivel grips to overcomes difficulties associated with stress concentrations and loading eccentricities that create nonuniform fracture planes.

- Includes GCTS CDT-CMOD extensometer with two or four sensors to servo control the average or the maximum carack mouth opening displacement rate.

Metal & Fiber Tension Grips

- ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products

Ductility Bend Fixture

- ASTM E290 Standard Test Methods for Bend Testing of Material for Ductility

Environmental Chamber (Coming Soon)

Enter your email below to stay on top of future information regarding our environmental chamber for the eFRM series.